Utility Locating & Ground Penetrating Radar (GPR) Services

Comprehensive Utility Locating & GPR Solutions

Holes Companies’ Technology Division delivers expert utility locating and Ground Penetrating Radar (GPR) services tailored for the needs of complex infrastructure projects. Our certified technicians use advanced technology to provide accurate subsurface mapping, ensuring safety and efficiency throughout your project lifecycle.

Certified Technicians & Advanced Equipment

- All GPR specialists are trained and certified by the Concrete Sawing and Drilling Association (CSDA).

- Many team members also hold NULCA certifications, demonstrating our commitment to industry best practices.

- We utilize state-of-the-art equipment for precise detection and mapping of underground utilities and structures.

Comprehensive Subsurface Detection Capabilities

- Identify and map building foundations, structural voids, piles, and pile caps.

- Detect metallic objects: underground storage tanks (USTs), steel pipes, manhole covers, wire mesh, rebar, conduit, and post-tension cables.

- Locate non-metallic utilities: gas pipelines, communication and data infrastructure, sewer lines, and PVC pipes.

Industry Applications

- Bridge anchoring scans for civil engineering projects.

- Pre-trenching utility assessments for chemical plants and LNG facilities.

- Post-tension cable location for safe coring and installation of MEP (Mechanical, Electrical, and Plumbing) systems.

- Services available to all sectors of the construction industry.

Risk Mitigation & Project Efficiency

- Accurate identification of underground hazards and obstructions reduces risk and prevents costly incidents.

- Our detailed mapping and reporting streamline workflows, saving valuable time and resources.

- Commitment to safety and project success ensures your team’s confidence from planning to completion.

Why Choose Holes Companies?

- Industry-leading expertise in utility locating and GPR services.

- Certified technicians committed to safety and precision.

- Advanced equipment and technology for reliable subsurface detection.

- Trusted partner for construction, infrastructure, and industrial projects.

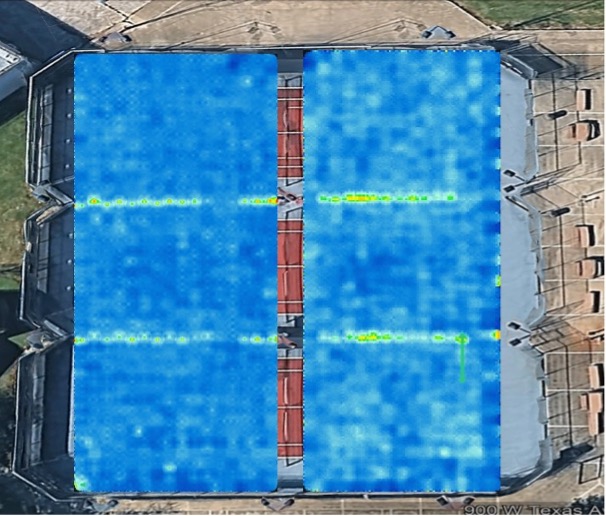

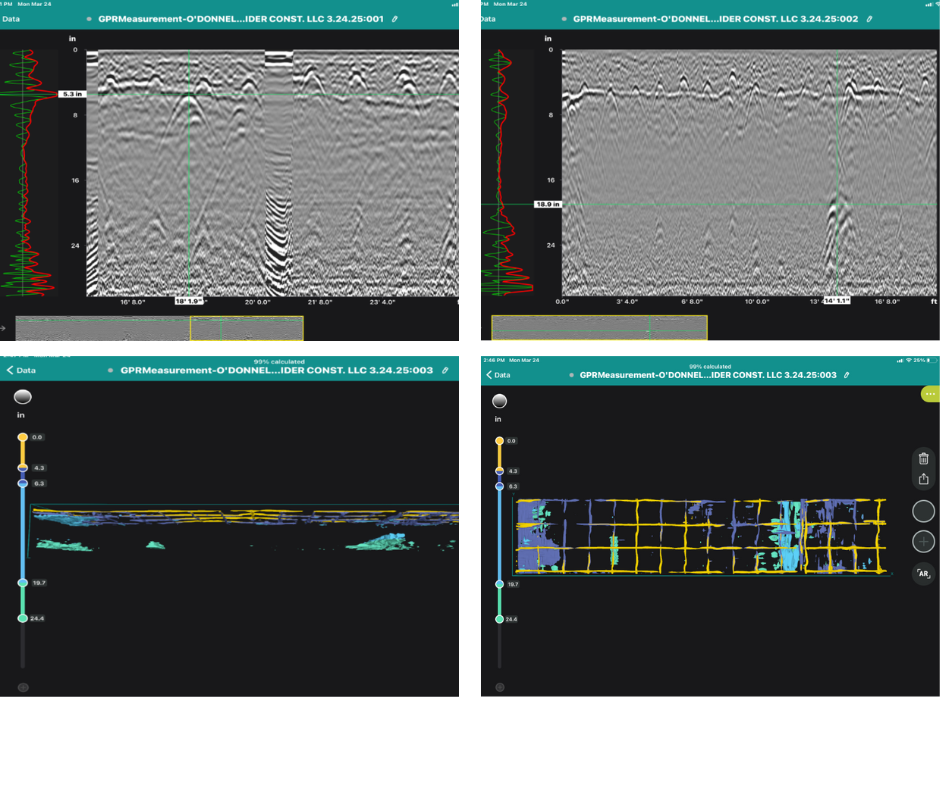

Solid Results. Real World Examples.

Commonly Asked Questions:

How does Holes Company’s utility locating process integrate with our pre-excavation workflow to ensure we meet critical project timelines?

Holes Companies utility locating process integrates directly into the pre-excavation workflow by providing timely, accurate subsurface information that allows construction activities to proceed without delays.

- Our team coordinates closely with your project managers and schedulers to ensure all locating activities are completed ahead of excavation, reducing the risk of unforeseen conflicts.

- We begin by reviewing your project scope and scheduled excavation areas, then dispatch certified technicians to perform comprehensive surface and subsurface scans.

- The findings are documented clearly and delivered promptly, enabling your team to validate design assumptions, adjust excavation plans if necessary, and maintain compliance with safety and regulatory requirements.

This proactive approach minimizes the potential for utility strikes, change orders, or downtime—ultimately supporting your ability to meet critical project deadlines with confidence.

Is scanning necessary before cutting or coring?

Certainly. Hitting a conduit or post-tension cable can halt work, cause delays, and result in costly repairs. Scanning beforehand ensures safety and prevents these issues.

Do you scan only concrete slabs or also walls?

We offer scanning services for foundations, walls, decks, and ceilings. Our GPR technology precisely locates embedded objects in vertical and overhead surfaces as accurately as it does in slabs.

Are reports provided for every scan?

Although we suggest customizable detailed reports that can provide you and your customer with documentation for future projects, on-slab markings can be adequate for pre-coring and pre-cutting tasks.

Can you provide specific case studies or data that quantify the time and cost savings previous clients experienced by utilizing your GPR services?

Due to our expertise, we provided 50% savings for our client at the Advario Galveston Project.

What is your accuracy rate for identifying non-metallic utility lines, and how does that data help us mitigate risk on this specific job site?

I would like to say that we strive for 100% accuracy, but we’re limited to the geophysical makeup of the material we are scanning/locating through.

Things this data helps for risk-mitigations:

- Confirming safe anchor/coring paths

- Planning excavation without utility conflict

- Protecting irrigation/drainage that could cause washout under slabs

- Avoid hitting private lateral lines not covered by 811

- Prevent unexpected shutdowns that cascade into crew downtime

- Engineers can redesign conflict areas

- Crews are given safe dig zones

- Work sequencing improvements

- Risks are documented in pre-task planning

- Stakeholders understand subsurface constraints

- Select safe coring locations

- Plan anchor placement

- Avoid cutting irrigation or drainage networks

- Prevent PT tendon conflict (often near non-metal conduit runs.)

What kind of documentation or reporting do you provide post-scan that an estimator can use for risk assessment and project planning?

The documentation/reporting we can provide is determined by what type of scanning is being done. We can customize the deliverables to the client’s needs, whether it be marked on the ground, or a computer-generated 3D model that could be overlayed onto Google Earth(subsurface). 3D models can also be generated for the area of concrete scanned.